Better color fidelity

Better image quality

Higher resolution

The most compelling combination of clarity, brightness, and color fidelity

Ferroelectric liquid crystal (FLC) is a type of liquid crystal called a smectic liquid crystal, which

consists of liquid crystal molecules arranged in layers. Compared to nematic liquid crystals used in

general LCDs, smectic liquid crystals have the advantage of a faster response time.

MDCA has a chemistry team that develops and manufactures original high-performance FLC, and has over 20

years of experience in providing FLCs for numerous products, particularly microdisplays.

Our FLC can realize a switching speed of 100 μs level at room temperature in both rise and fall. This is

10 to 100 times faster than general nematic liquid crystals. This feature makes FLC is suitable for

optical shutters, for example.

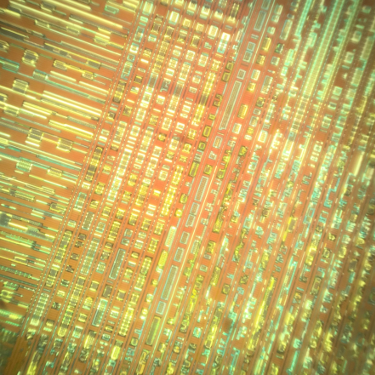

Also, our FLC has little crosstalk between adjacent pixels. This makes FLC useful for microdisplays or SLM

having ultra-fine pixels with a pixel pitch of 3 μm or less.

Liquid Crystal on Silicon (LCOS) is a reflective active-matrix liquid-crystal microdisplay using a liquid

crystal layer on top of a silicon backplane. It is also used as a Spatial Light Modulator (SLM).

MDCA has extensive experience and knowledge designing custom Very Large Scale Integration (VLSI) chips for

FLCOS (LCOS using FLC) backplanes. We also can provide VLSI chip design support services for customers who

wish to fabricate their original FLCOS.

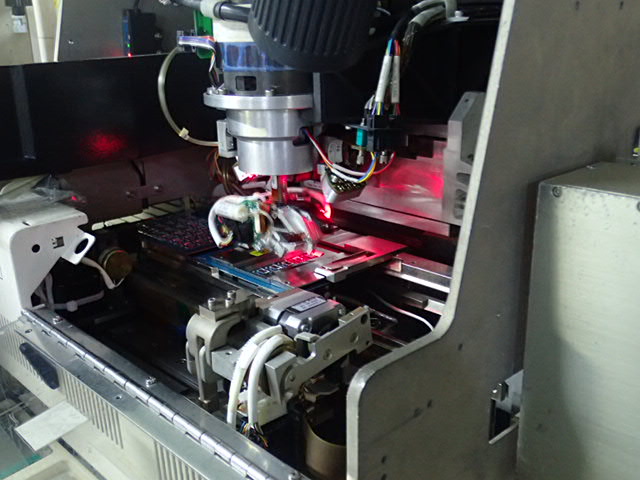

Citizen Finedevice (CFD), the Japanese parent company of MDCA, has an LCOS microdisplay production line

and has produced a number of FLCOS products. They have the necessary technology and equipment for glass

lamination, LC injection, dicing, assembly, optical inspection, etc.

CFD provides contract manufacturing services for microdisplays using their production line, assembling

silicon wafers and other materials provided by customers into complete modules. CFD also provides

development support, including the design of PCBs, FPCs, lenses and optical components to be combined with

microdisplays.